More you can find useful tools in our design and creativity category.

Capabilities that matter

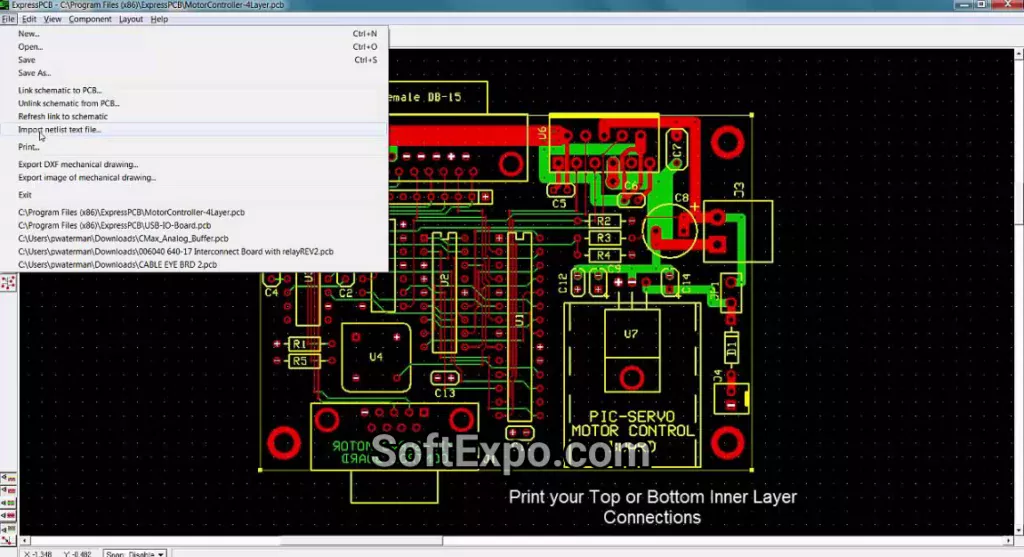

Designers can place components, route copper, and run DRC directly in ExpressPCB Plus, using highlight net to validate connectivity before generating an in‑app quote and placing an order to the board house. Constraints include no non‑plated holes and no internal slots/cutouts at this time, which should be considered when planning footprints, panelization, or mechanical features.

Schematic capture and libraries

Projects typically begin in ExpressSCH (packaged with the installer), enabling schematic capture that pairs with Classic today while the Plus layout emphasizes its own integrated checks and workflow for new users. Parts can be accelerated via the platform’s library ecosystem and integrations such as SnapEDA to reduce symbol/footprint creation time and improve consistency across designs.

Manufacturing services and specs

The Express PCB Manufacturing Service offers Standard, MiniBoard, Proto, and Production options with typical lead times from 1–5 days depending on layer count and service tier, helping teams align cost and speed to project phase. Typical capabilities include fine features down to a minimum 0.005 in trace/space and larger panel sizes up to 12×14 in for many Plus Standard orders, with options scaling to higher quantities as runs move from prototype to production.

Quality, markings, and logistics

For traceability, orders can include UL, lot code, and date code markings so teams meet compliance or internal process controls without extra vendor coordination. Operational details such as an afternoon Pacific cut‑off help align submission timing with same‑day queueing, which is practical during rapid prototyping sprints or tight revision cycles.

Who benefits most

- New learners and educators get a gentle learning curve, free tools, and built‑in checks that shorten time to a working 2‑layer board without wrestling with complex CAD administration.

- Startup and hobby projects benefit from MiniBoard and Proto services plus 1–3 day options that accelerate iteration without sourcing separate fabrication vendors or quote portals.

- Small engineering teams appreciate in‑app quote and order, multilayer support, and standardized markings that streamline documentation while keeping procurement simple.

Practical workflow

Download and install ExpressPCB Plus, open or create a new design, and ensure DRC is configured to match the service constraints for trace/space, drills, and soldermask for a clean fabrication handoff. Capture the circuit in ExpressSCH or import library parts, place and route in Plus, validate with highlight net and DRC, then use the integrated quote and order panel to select MiniBoard, Standard, Proto, or Production based on layer count, quantity, and lead time.

Pro tips for reliable results

Keep vias and annular rings consistent with the drill table and avoid non‑supported features like internal cutouts or non‑plated holes to prevent order holds or redesigns late in the cycle. For multilayer designs, define whether inner layers function as planes or signals early, and leverage top and bottom silkscreen plus editable soldermask to clarify assembly, test points, and polarity at fab and bring‑up.

Bottom line

ExpressPCB combines approachable PCB layout in ExpressPCB Plus with direct, U.S.-based manufacturing, giving makers and engineers a streamlined path from schematic capture to a finished 2–6‑layer PCB with predictable pricing and short lead times. With integrated DRC, highlight net, BOM, editable soldermask, and in‑app quote and order, it’s a pragmatic choice for first prototypes through small production runs without overcomplicating the toolchain.

Frequently Asked Questions about Free Download ExpressPCB

1. Does ExpressPCB support Gerber file export?

ExpressPCB Classic does not export standard Gerber files and is optimized for ordering through the ExpressPCB PCB fabrication service. ExpressPCB Plus enables Gerber file export so you can manufacture your boards with third‑party PCB manufacturers.

2. Does ExpressPCB include schematic capture (ExpressSCH) and netlist?

Yes. The suite includes ExpressSCH for schematic capture. You can generate a netlist, link it to the PCB layout, forward‑annotate changes, and run electrical and design rule checks to validate your PCB design before fabrication.

3. What are ExpressPCB system requirements for Windows 10/11?

ExpressPCB runs on Windows 10/11 (64‑bit recommended). The tools are lightweight and work on modest hardware; a modern dual‑core CPU and 4–8 GB RAM are typically sufficient for small to medium PCB layouts. There is no native macOS or Linux version, though some users run it via virtualization or compatibility layers.