All rights reserved © 2026

Materialise Magics is an industry‑leading 3D printing data and build preparation software that sits between your CAD tools and industrial 3D printers. It cleans, repairs, and optimizes parts, then prepares build platforms, support structures, and machine‑ready files so additive manufacturing runs faster and fails less often.

Materialise Magics software is both a powerful STL editor and a full data and build preparation environment for additive manufacturing workflows. It imports almost all common CAD and mesh formats, preserves color information, repairs broken STL files, and converts surfaces into watertight solids ready for printing.

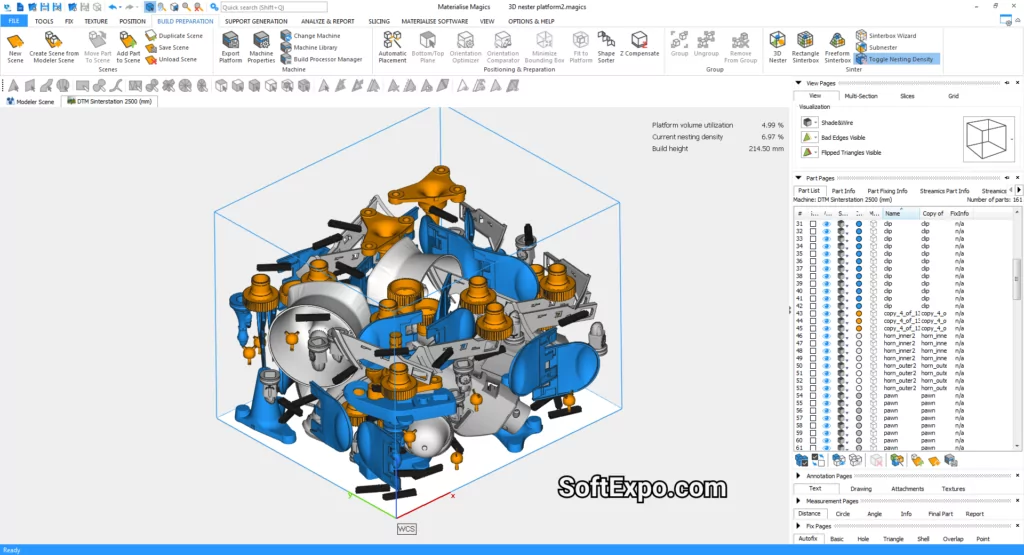

Once geometry is clean, Magics takes over as your 3D printing software for build preparation: nesting, orientation, support generation, slicing, and build report generation all happen inside one interface. The goal is consistent, on‑spec parts across technologies like laser sintering, SLM/DMLS, SLA, and polymer powder‑bed systems, with fewer manual touch‑ups.

As a 3D printing STL editor, Materialise Magics offers automatic and manual repair tools that fix inverted normals, self‑intersections, gaps, and non‑manifold edges before they turn into build failures. You can hollow and perforate parts, apply Boolean operations, cut models intelligently, extrude features, offset walls, and add text or logos, all with printability in mind.

For build preparation, the Nester module delivers both manual and automatic 3D nesting, helping you reach high packing density on powder‑bed fusion systems while protecting fragile features. Orientation tools and slice previews let you balance support volume, surface quality, and build time before committing a job to the machine.

Support generation is handled through dedicated modules like e‑Stage and e‑Stage for Metal+, which automate support structures for resin and metal 3D printing to cut material usage and post‑processing labor. The Materialise Structures module creates lattice structures that reduce weight and material consumption while maintaining strength and stiffness, which is crucial for high‑value aerospace, medical, and lightweighting applications.

Magics connects to printers via Materialise Build Processors, translating prepared builds into optimized machine instructions and enabling advanced features like parameter control and build status reporting. Because the platform is technology‑neutral, the same Materialise Magics 3D Print Suite can support mixed fleets of metal and polymer machines from many OEMs.

In a typical Materialise Magics tutorial or training, the workflow starts by importing CAD or STL files from design tools into Magics, then immediately running an STL repair and quality check. Engineers then use the STL editor and CAD enhancement tools to hollow, cut, label, and otherwise adapt parts so they are printable and optimized for an additive process rather than subtractive thinking.

Next comes build preparation: duplicating parts as needed, orienting them for optimal surface finish and support removal, and using 3D nesting to fill the build volume efficiently. With Magics, many repetitive steps—such as investment‑casting trees, dental build plates, or serial production nests—can be standardized and reused across jobs.

Support generation follows, using process‑specific modules to create supports for SLM/DMLS, SLA, and other technologies, with analysis tools to spot overhang risks, collisions, or insufficient anchoring. Finally, Magics slices the build, sends it to the correct machine through a Build Processor, and can generate detailed build reports for traceability and quality control.

Treat Materialise Magics as your additive manufacturing data‑preparation hub: keep all STL repair, build platform preparation, 3D nesting, and support strategies inside Magics, and use CAD only for design intent. Standardize Magics projects and templates per machine and material so operators can reuse proven lattices, support styles, and orientation rules instead of reinventing them for each build.

When scaling production, lean on Magics’ reporting, measurement, and simulation features to close the loop between build results and pre‑print decisions, not just fix geometry. For metal 3D printing, pair Materialise Magics with modules like e‑Stage for Metal+ and Structures to reduce support touch points and part weight, improving both economics and downstream machining.