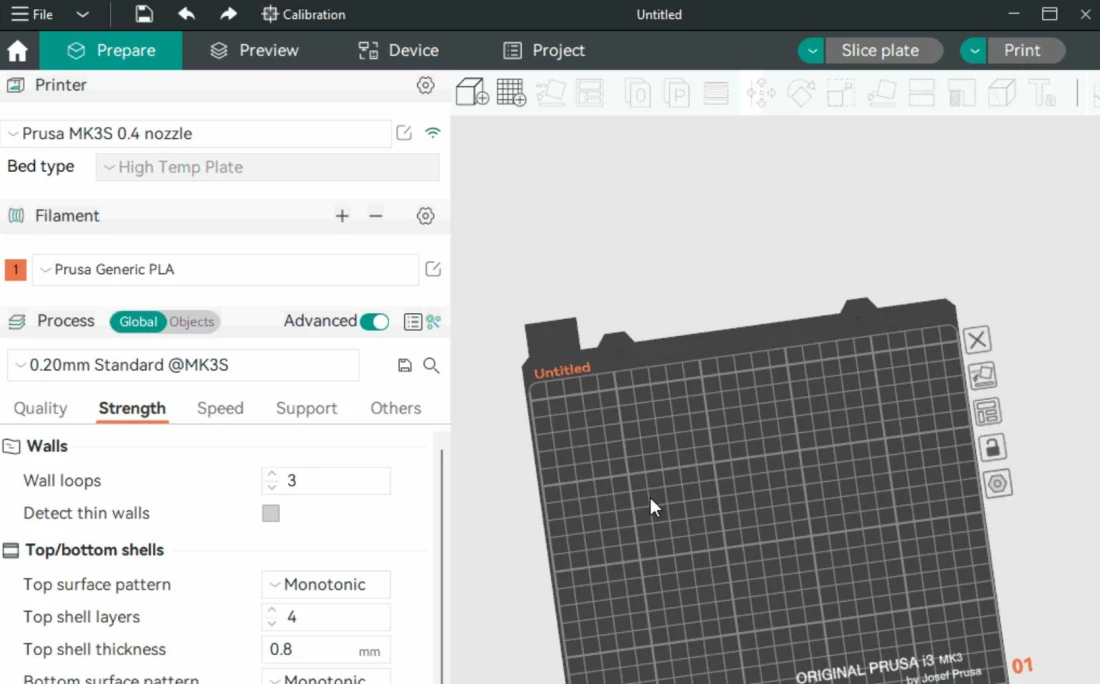

Orca Slicer is a sophisticated, open-source 3D printing software that has rapidly become a favorite among makers for its ability to bring advanced, Bambu Lab-style features to a wide range of third-party printers. Originally forked from Bambu Studio and PrusaSlicer, this powerful G-code generator bridges the gap between ease of use and granular technical control, offering a unified workflow for hobbyists and professionals alike. By integrating comprehensive calibration tools directly into the interface, it eliminates the need for external test prints or manual script editing, allowing users to fine-tune their machines for perfect dimensional accuracy and surface finish. Whether you are running a high-speed Voron, a reliable Creality bed slinger, or a print farm of mixed machines, Orca Slicer provides a modern, fluid experience compatible with Windows 10 and Windows 11.

Key Features

- Built-in Calibration Suite: Includes automated generation for essential tests like flow rate, pressure advance, retraction, and temperature towers, enabling users to dial in filament settings without leaving the slicer.

- Multi-Plate Project Management: Allows you to arrange and slice multiple build plates within a single project file, making it incredibly efficient to organize large prints or multi-part assemblies.

- Native Klipper Integration: connects seamlessly with web interfaces like Mainsail, Fluidd, and OctoPrint, permitting direct Wi-Fi uploads and real-time printer monitoring from the device tab.

- Sandwich Mode Infill: Utilizes an optimized infill strategy that improves the visual clarity of transparent filaments and structural integrity by adjusting how internal layers are stacked.

- Mouse Ear Brims: Features a specialized brim type that automatically adds adhesion discs to sharp corners, effectively preventing warping without requiring a full brim around the entire model.

- Precise Wall Generators: Offers advanced algorithms like Scarf Seams and precise outer wall positioning to hide layer starts and ensure dimensionally accurate mechanical parts.

Use Cases

This software is the ideal solution for 3D printing enthusiasts and engineers who operate custom-built printers or modified commercial machines (such as Voron, RatRig, or Ender series) and require deep control over slicing parameters. It is also excellent for print farm operators who need to manage complex, multi-part projects across different printer models using a single, cohesive interface.

With its rapid development cycle and community-driven feature set, Orca Slicer stands out as a superior choice for users who want the modern interface of Bambu Studio paired with the universal compatibility and technical depth needed for high-performance 3D printing.

Version 2.3.1 — October 2025

- Added "Extra Solid Infill" feature: Users can now reinforce specific sections of a model by inserting solid layers at custom heights without altering the overall infill density.

- New Fuzzy Skin capabilities: Introduced a "Fuzzy Skin Painting" tool to apply textures to targeted areas and a new "Extrusion Mode" for generating fuzzy skin based on flow rather than displacement.

- Improved Infill Rotation controls: implemented a template-based system for sparse infill rotation that prevents conflicts with direction settings and offers more consistent internal structure handling.

- Expanded Printer & Language Support: Added built-in profiles for Sovol SV08 MAX, Flyingbear, and Rolohaun Delta Flyer, plus updated Portuguese and Turkish translations.

- Fixed Prusa model identification: Resolved a regression bug where Prusa MK3S and MINI printers were incorrectly detected.

- Fixed 3MF import crash: Addressed stability issues when loading geometry-only 3MF files saved from alpha versions.

- Optimized Z-axis movement: Enhanced G-code generation for smoother Z-axis travel and disabled "smooth spiral" during input shaping calibration to prevent data interference.