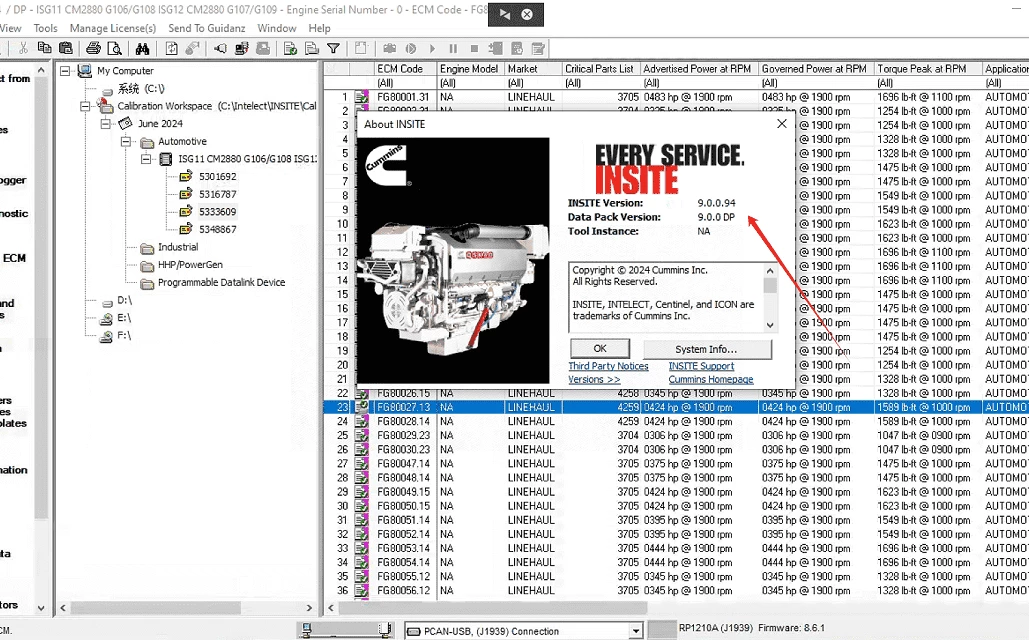

Cummins INSITE is a specialized electronic service tool designed to troubleshoot, diagnose, and maintain Cummins engines with dealer-level precision. By establishing a direct link to the Engine Control Module (ECM), this software enables technicians to minimize vehicle downtime through accurate fault code analysis and comprehensive repair guidance. Whether you are working on heavy-duty on-highway trucks or industrial construction equipment, the application serves as the primary interface for interpreting engine data and applying factory-approved calibrations.

Key Features

- Advanced Fault Code Diagnostics: Instantly reads active and inactive error codes, providing proprietary Cummins descriptions that explain the root cause rather than just displaying a generic number.

- Integrated Troubleshooting Workflows: Connects specific fault codes directly to step-by-step repair trees, wiring diagrams, and sensor location maps to guide mechanics through the correct repair procedure.

- ECM Calibration (INCAL): Allows authorized users to update the Engine Control Module with the latest factory performance files, ensuring engines meet current emission standards and performance targets.

- Real-Time Data Monitoring: Tracks live engine parameters such as fuel pressure, temperature, and turbo boost during road tests to identify intermittent issues that do not trigger an immediate fault code.

- Parameter Adjustment: Enables the modification of specific vehicle settings, including road speed governors, idle shutdown timers, and PTO configurations, to match fleet operational requirements.

- Trip and Vehicle Information: Extracts detailed reports on fuel consumption, driver behavior, and engine duty cycles to help fleet managers optimize maintenance schedules.

Use Cases

This software is essential for commercial fleet managers who need to track fuel economy and enforce speed limits across their vehicles, as well as independent diesel technicians who require dealer-grade access to reset operational restrictions on mining and agricultural machinery. It effectively supports modern workshop environments running Windows 10 or Windows 11 by streamlining complex diagnostic tasks into manageable steps.

For professionals responsible for maintaining Cummins-powered assets, this diagnostic suite offers the most reliable path to accurate repairs and prolonged engine life.

Version 9.3.0.22 — December 2025

- Enhanced ECM Compatibility: Added full support for post-2024 engine architectures, including X15 Performance and X12 Efficiency models compliant with EPA 2025 and Euro VI Step E standards.

- System Architecture Alignment: Synchronized the core application with Data Pack version 9.3.0 DP to eliminate parameter mismatches and ensure complete fault description availability across all supported platforms.

- Connection Stability: Improved the communication handshake process to reduce timeout errors and accelerate initial connection times with protected Electronic Control Modules (ECMs).

- Real-Time Monitoring: Refined parameter streaming accuracy, correcting sensor scaling discrepancies and removing deprecated data points for cleaner live monitoring.

- Calibration Fixes: Resolved specific connectivity issues during calibration downloads for QSK19/45/60 and QSM11 modules when using J1708 protocols.

- Platform Optimization: Optimized background service performance and memory management specifically for Windows 11 environments to prevent diagnostic session interruptions.

- Security Updates: Implemented stricter Master Password handling to prevent modules from entering a ROM Booted state during calibration attempts.