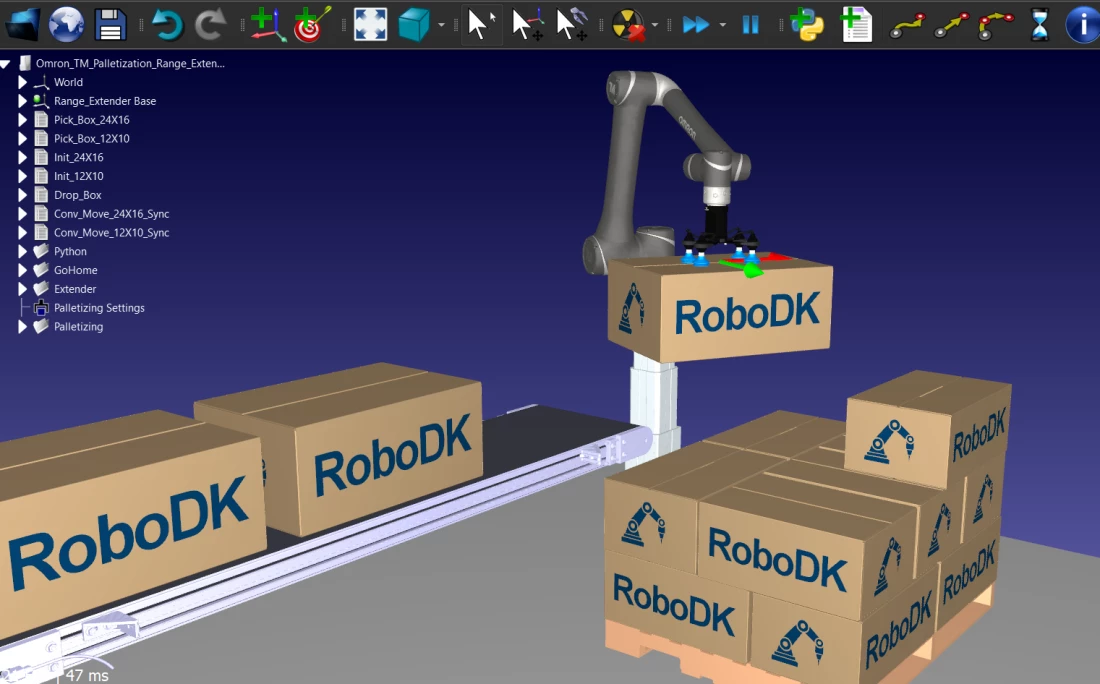

RoboDK stands as a premier offline programming and simulation platform designed to bridge the gap between digital design and physical manufacturing, allowing engineers to program industrial robots without disrupting production lines. This simulator empowers users to create error-free robot programs from the comfort of a desk, eliminating the costly downtime associated with traditional shop-floor programming. By supporting a vast array of robotic arms and manufacturing scenarios, RoboDK v5.9.5 ensures that complex automation tasks—from simple pick-and-place operations to intricate multi-axis machining—are executed with mathematical precision.

Key Features

- Universal Offline Programming (OLP): Generates vendor-specific code for over 1,200 robot controllers (including ABB, KUKA, FANUC, and Universal Robots), allowing users to program nearly any industrial arm without learning manufacturer-specific languages.

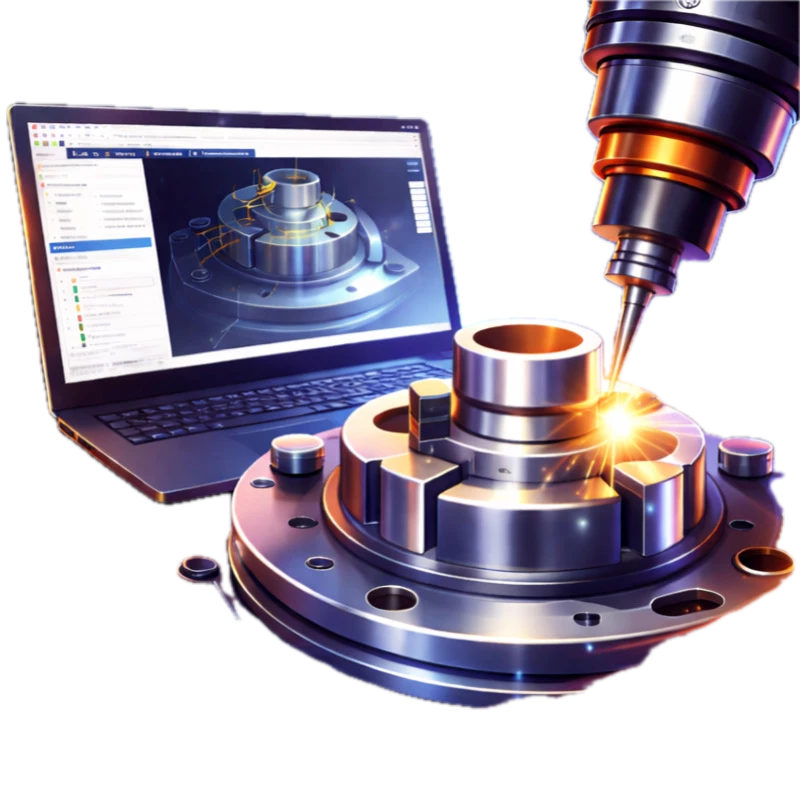

- Native Robot Machining (CAM): Converts CNC machine code (G-code) and APT files directly into robot control programs, effectively turning a standard 6-axis robot into a versatile 5-axis CNC milling machine for sculpting, drilling, and cutting.

- Digital Twin & Collision Detection: Visualizes the entire work cell in a virtual 3D environment to identify singularities, axis limits, and potential collisions before a single real-world movement occurs, significantly reducing risk and setup time.

- Automated Path Optimization: Automatically computes the most efficient tool paths and robot configurations, smoothing out movements to prevent jerky transitions and ensuring consistent cycle times for high-precision tasks.

- Extensive Robot Library: Provides instant access to a constantly updated online marketplace containing thousands of industrial robot models, external axes, and tools, ensuring compatibility with virtually any hardware setup found in modern factories.

- Python API & Add-in Integration: Offers a robust Python API and a dedicated Add-in Manager that allows advanced users to automate repetitive simulation tasks, integrate with external measurement systems, or develop custom plugins for specialized workflows.

Use Cases

RoboDK is indispensable for manufacturing engineers and integrators who need to deploy automated cells for tasks like robotic milling, welding, 3D printing, and dispensing without halting active production lines. It is particularly effective for job shops moving from manual labor to automation, as well as educational institutions teaching Industry 4.0 concepts using diverse hardware brands on a unified software platform.

With its brand-agnostic approach and ability to handle complex manufacturing paths that traditional teach pendants cannot manage, RoboDK offers a flexible, cost-effective alternative to rigid proprietary software ecosystems.

Version 5.9.5 — December 2025

- Enhanced the driver functionality for Leica laser trackers to ensure better connectivity and performance.

- Fixed an issue where robot tools were not loading correctly for CNC-style robots, such as MABI systems.

- Improved the accuracy of cycle time estimates when exporting simulations to HTML.

- Updated license status messages to provide clearer information to the user.

- Refined mesh optimization settings, offering more control over 3D model performance.

- Upgraded post processors for JAKA robots and renamed/improved the Schneider Electric post processor.

- Modified the plugin manager to display the list of unloaded default plugins by default.

- Streamlined the calibration measurements menu for better usability.

- Enhanced the API capabilities for constructing and managing external axes.